"Star Arrow One Street" lights up the industrial cluster

Automatic capture, visual positioning, and mechanical perception. In just a few seconds, the parts are placed to the specified location, the warehouse, assembly, general installation, test ... tens of thousands of satellite parts automatically enter the warehouse, distribution, production process according to the instruction, the production process, the production process, and the production process.Completely realize intelligence.

In Wuhan National Aerospace Industry Base Satellite Industrial Park in Wuhan National Aerospace Industry Base in Xinzhou District, Hubei Province, the nation's first small satellite intelligent production line built and operated by Aerospace Science and Industry Space Engineering Development Co., Ltd. is busy.Different from the traditional laboratory, it is more like a car factory. From parts to the whole star assembly and quality inspection, the manufacturing of a satellite is decomposed into several links, and the quality efficiency is greatly improved.

"After continuous iteration and optimization, this production line can achieve flexible co -production of different types of satellites, and the production efficiency has been greatly improved." Yi Ming, a dispatcher of the Intelligent Manufacturing Division of Aerospace Science and Technology Space Engineering Development Co., Ltd.For the "star -making factory" produced by various satellites, the company has been completed and put into investment in more than 200 small satellites in the past three years.

As the first commercial aerospace industry base in the country, since the construction of Wuhan National Aerospace Industry Base in 2017, it has been led by rockets and satellite manufacturing companies to promote the accelerated gathering of upstream and downstream chains such as remote sensing, aerospace materials, measurement and control., Cloud and Aerospace materials gathering industrial clusters.

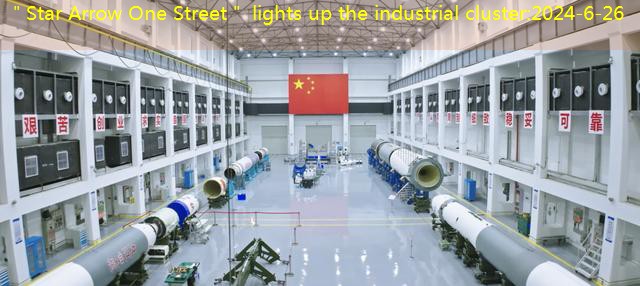

It is only one street from the "satellite factory". In the installed workshop of Aerospace Science and Technology Rocket Technology Co., Ltd., a fast boat series rockets equipped with satellites are undergoing the final test and inspection.

The picture shows the production workshop of Aerospace Science and Technology Rocket Technology Co., Ltd.(Photo Conferring in Aerospace Science and Technology Rocket Technology Co., Ltd.)

"Load rockets are the only entrance to and from space, which is related to the foundation of the development of the commercial aerospace industry." Liu Xin, deputy general manager of Aerospace Science and Technology Rocket Technology Co., Ltd., told reporters that the company's "Kuaizhou No. 1" has now become an active service in my country. The solid carrier rocket with the most launch times, the industrial park can produce up to 50 rockets each year.From the end of last year to the beginning of this year, the four "Kuaizhou No. 1" rockets who entered the same battles achieved "four rounds" within 18 days.

According to the reporter's understanding, just two months ago, the 70 -ton level of "Mingfeng" No. 2 can reuse the use of liquid oxygen methane engines to take multiple ignition, all succeeded.This will provide motivation for subsequent liquid rockets that can be reused.

The picture shows the production workshop of Aerospace Science and Technology Rocket Technology Co., Ltd.(Photo Conferring in Aerospace Science and Technology Rocket Technology Co., Ltd.)

"'Star Arrow One Street' to make the distance and time of the docking test greatly shortened. Satellite and rockets are connected at the end of the rocket and then handled them together, which not only improves the overall launch service performance efficiency, but also saves customer costs." Aerospace Science and Technology Rockets have limited technologyDaiyi, deputy director of the company's total decoration workshop.As the performance of Kuaizhou Rockets entered the stage of batch production, batches, and group batch launch, a variety of new rockets developed in parallel, and the demand for parts, workflows, and process processing rose straight, and the industrial cluster advantages of the space base showed.

Not only is the connection between upstream and downstream enterprises in the industrial chain, but also in Xinzhou District, Wuhan City, where the space base is located, many companies including Wuchang Shipbuilding Industry and Huaxia Jingchong have been incorporated into the aerospace industry chain by contracting work processing and process welding."Friends", and promoted industrial upgrading through improvement of aerospace quality culture and building aerospace industry standards.

As of now, Wuhan National Space Industry Base has exported 17 industrial projects, with a total investment of nearly 16 billion yuan. The main chain of the industry has become clearer and complete, becoming another heavyweight engine that supports high -quality economic growth in Wuhan.(Reporter Xiong Qi, Gong Liankang)

【Source: Xinhua News Agency】